Monitoring and maintaining optimal water quality parameters is crucial for efficient and safe operation of HVAC systems, boilers, cooling towers, humidifiers, and other equipment. Regular water testing, proper water treatment, and adherence to recommended guidelines will help mitigate these potential issues, will save your company thousands of dollars in operating expenses, and can spare you costly environmental and legal fees due to hazards that can be prevented.

-

The pH is too high

This will lead to scale formation in pipes and equipment, reducing heat transfer efficiency and increasing energy costs. This will also cause corrosion in metal components.

-

The pH is too low

This will lead to corrosion of metal components, leading to leaks and equipment failure. It will also cause an increased risk of releasing heavy metals into the water.

-

TDS (total dissolved solids) is too high

This will lead to scale buildup in pipes, heat exchangers, and cooling towers; thereby, reducing heat transfer efficiency. This will also cause an increased risk of corrosion due to elevated mineral content.

-

TDS (total dissolved solids) is too low

This will cause corrosion of metal components due to lack of protective mineral content in the water. This will also reduce efficiency of your water treatment chemicals. (Ditch them.)

-

Conductivity is too high

If the conductivity is too high, this will lead to scale formation and corrosion.

-

Conductivity is too low

If the conductivity is too low, this may indicate poor water quality or insufficient dissolved ions, which will affect the performance of water treatment chemicals. (Again, ditch them.)

-

Hardness as CaCO3 is too high

This will cause scale formation in pipes, boilers, and heat exchangers, reducing heat transfer efficiency and increasing energy consumption. This will also lead to an increased risk of mineral buildup in equipment.

-

Hardness as CaCO3 is too low

This will cause corrosion of metal components due to lack of protective mineral scale. It can also lead to reduced effectiveness of certain water treatment processes.

-

Alkalinity is too high

This will contribute to scale formation and reduce the effectiveness of water treatment chemicals. (You know how we feel about those by now.) High alkalinity may also lead to pH spikes if not properly controlled.

-

Alkalinity is too low

Low alkalinity causes reduced buffering capacity, leading to pH fluctuations and potential corrosion issues.

-

Free chlorine and total chlorine is too high

This will lead to corrosion of metal components. It will also accelerate degradation of rubber seals and gaskets.

-

Free chlorine and total chlorine is too low

This will lead to inadequate disinfection, increasing the risk of microbial growth in water systems.

-

Dissolved iron and particulate iron is too high

This will cause staining of fixtures and surfaces due to rust formation. It will also increase the risk of corrosion in equipment and pipes.

-

Dissolved iron and particulate iron is too low

This is ideal to prevent staining and corrosion issues.

-

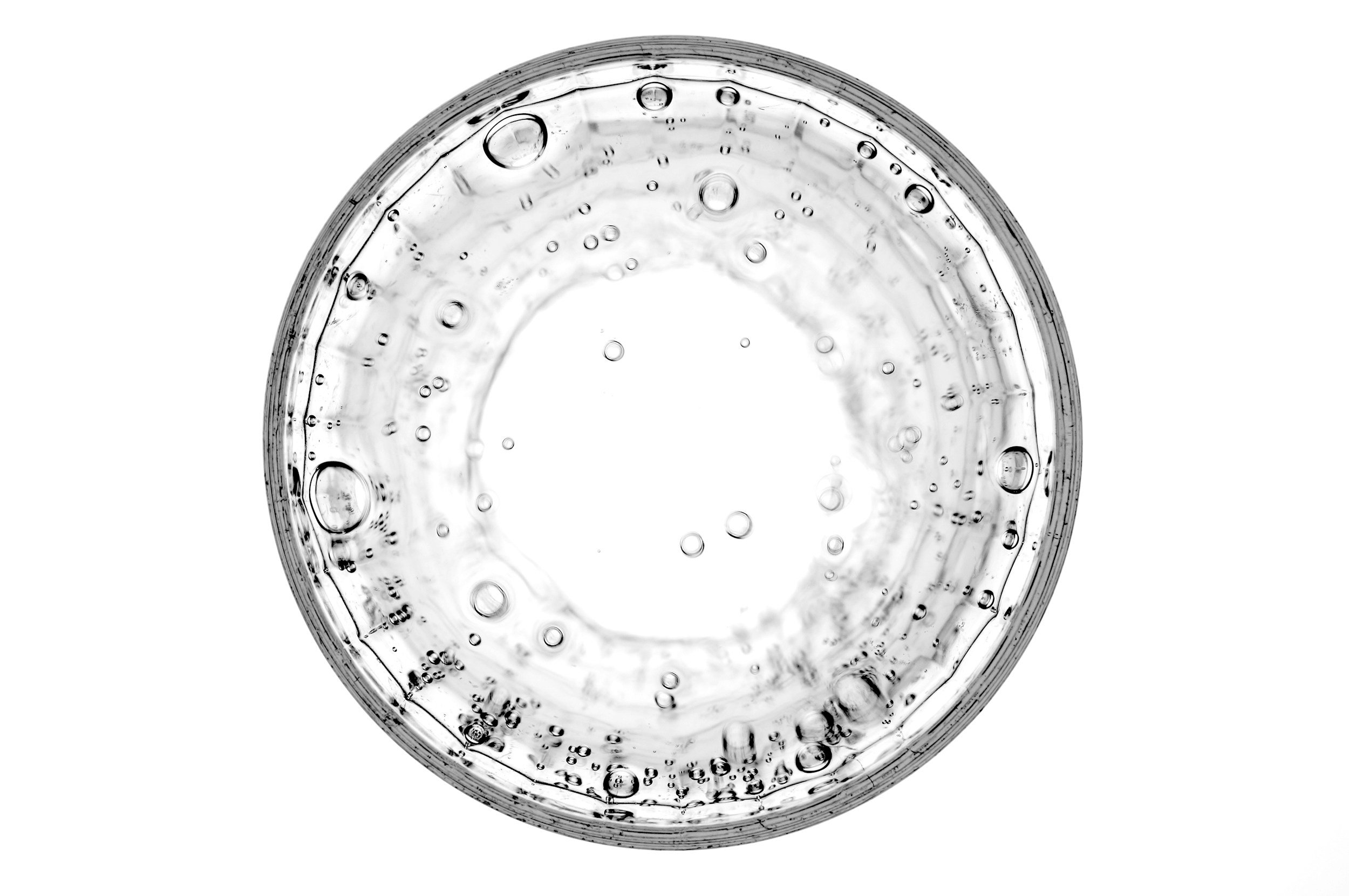

Water opacity is too high

This indicates high levels of suspended solids or organic matter, leading to fouling of equipment and reduced efficiency. This will create an increased risk of clogging filters and strainers.

-

Water opacity is too low

This is typically desired for clearer water and better system performance.

-

Bacteria is too high

This will lead to biofilm formation, fouling of equipment, and potential health hazards. This will also create an increased risk of Legionella growth in water systems, especially in cooling towers and humidifiers.

-

Bacteria is too low

This is desired for safe and sanitary water systems, reducing the risk of microbial contamination and associated problems.